Home

>

Home

>

- Products >

- RFID Inlay/ Label >

-

View More

View More

Alien H3 RFID Patch Tag Sticker Label UHF Tire Tag

Heat Resistant Alien H3 RFID Patch Tag Sticker Label UHF Tire Tag for Car Tire Tracking

-

View More

View More

I CODE SLI HF NFC RFID Label for Library book

High frequency library tags, utilizing RFID technology, offer fast and accurate book identification

-

View More

View More

UHF EPC RFID Label Library Sticker Tags

This label can help librarians encode book information into RFID tags, and then perform tag data

-

View More

View More

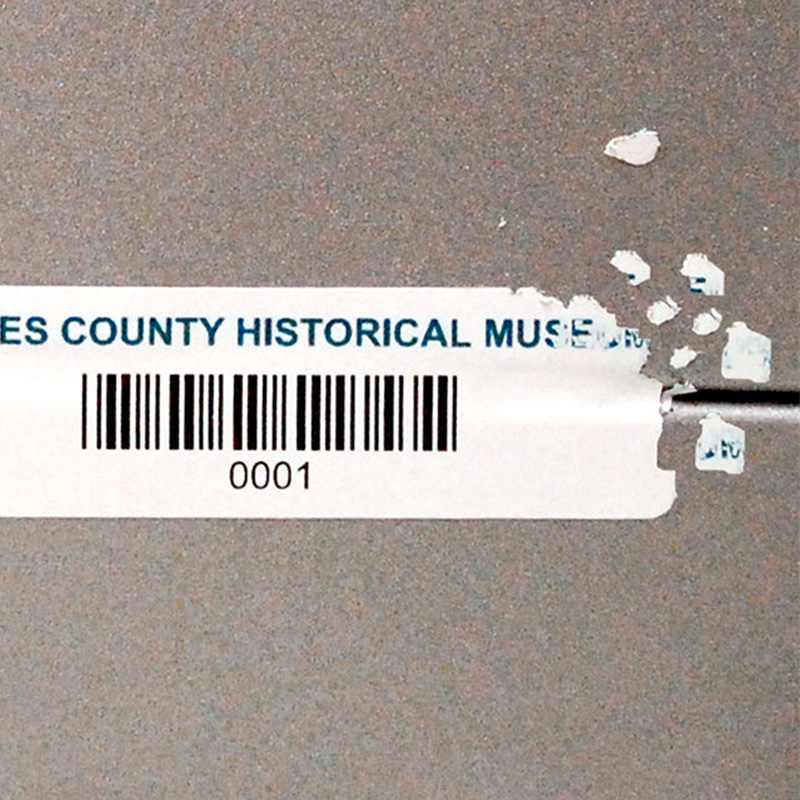

Custom 13.56MHz Anti-Counterfeit Label RFID Sticker

RFID anti-counterfeit labels are designed to combat counterfeit products by incorporating an RFID

-

View More

View More

RFID Anti-Counterfeit Label Tamper-Proof RFID Sticker

RFID anti-counterfeit labels are designed to combat counterfeit products by incorporating an RFID ch

-

View More

View More

Vehicle Tracking Windshield RFID UHF Stickers

UHF RFID Tag Long Range Read Vehicle Tracking Windshield RFID UHF Stickers

-

View More

View More

UHF Car Headlamp R6-P Windshield Sticker

ISO18000-6C Waterproof UHF Car Headlamp R6-P Windshield Sticker RFID Inlay RFID Sticker

-

View More

View More

Waterproof and heat resistant RFID Jewelry Label

UHF 860-960Mhz PET Waterproof and heat resistant RFID Jewelry Label

ADVANTAGES

Our extensive experience and versatile production capabilities allow us to provide comprehensive and customized solutions, meeting a wide range of market demands.

-

DIVERSE PRODUCT RANGE

We offer a wide array of card types, including AES cards, transit cards, menu displays, white RFID cards, and wooden cards, designed to meet the diverse needs of our clients.

-

CUSTOMIZATION SERVICES

Our ability to personalize products, such as imprinting "Your Logo" on wooden cards, ensures that we can tailor our offerings to meet specific client requirements.

-

HIGH-QUALITY MATERIALS

We use both plastic and wood materials, demonstrating our commitment to using only the highest quality materials and showcasing our exceptional craftsmanship.

-

MULTIFUNCTIONALITY

Products like our menu displays with QR codes offer additional functionalities, enhancing the practicality and appeal of our cards.