Effective tracking and management of products is important in business cost management.Radio Frequency Identification (RFID) is one of the key technologies enabling automation and real-time visibility. Among the different RFID types, Ultra High Frequency (UHF) RFID stands out for its long read range and high-speed data transmission, making it a preferred choice in logistics, retail, and manufacturing.

UHF, or Ultra High Frequency, refers to the radio frequency range of approximately 860 to 960 MHz. In RFID systems, UHF is primarily used with passive RFID tags, which operate without their own power source.

Thanks to the higher frequency band, UHF RFID systems can read tags from a distance of 8 to 10 meters, making them ideal for environments where long-range, automated data capture is required. This is particularly useful in sectors like logistics, warehousing, and inventory management, where portable UHF handheld readers are widely used.

A typical UHF RFID system consists of three key components:

Tags (transponders)

Antennas

RFID readers

The tag contains a microchip and an antenna. The reader emits an electromagnetic field, which powers up the tag’s chip through induction. Once activated, the chip uses the antenna to send its stored data back to the reader. This entire process happens wirelessly and almost instantly, without the need for the tag to have a battery.

As global supply chains become more complex, companies are looking for smarter ways to monitor product movement and reduce manual work. UHF RFID plays a key role in this transformation by offering real-time data collection, which leads to faster and more accurate operations.

Below are the main advantages of integrating UHF RFID into business processes:

UHF RFID allows for the simultaneous reading of over 100 tags per second. This makes inventory checks significantly faster and more accurate than manual barcode scanning. It also helps businesses reduce excess stock and fulfill orders more efficiently.

Each RFID tag can carry a unique identifier, making it possible to track an individual item throughout the entire supply chain—from raw material sourcing to the end consumer. This improves transparency and supports anti-counterfeiting efforts.

UHF RFID tags can be read from several meters away, without needing a direct line of sight. As long as a tag enters the antenna’s reading field, it can be identified instantly. This reduces the time needed for warehouse operations by up to 50%, especially in high-volume environments.

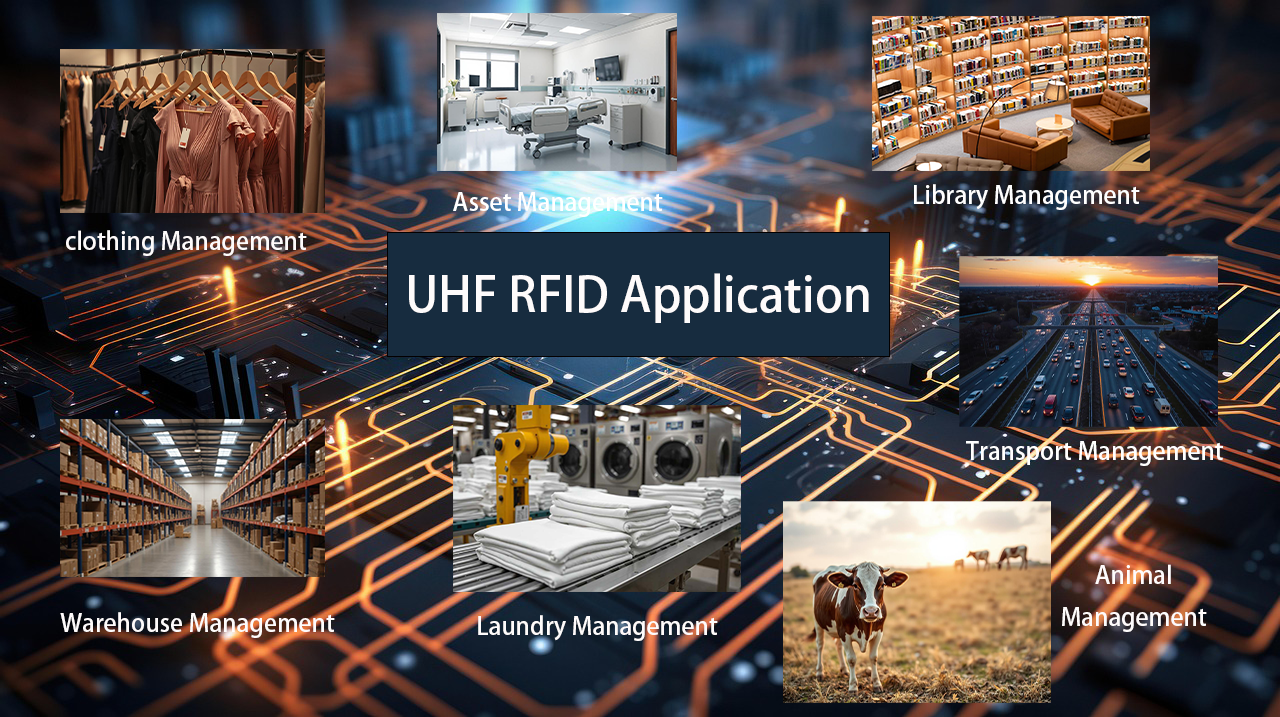

The advantages of UHF RFID have led to its widespread adoption not only in retail but also across various industrial sectors. These include:

Automotive

Aerospace

Pharmaceuticals

Cosmetics

Food and beverage

Healthcare

In these industries, UHF RFID supports automated inventory, real-time tracking, anti-theft systems, and even patient identification in medical facilities. UHF RFID portals connected via IP or Wi-Fi enable instant, remote updates of stock levels and item status across departments.

UHF RFID technology brings remarkable benefits to businesses by enabling fast, long-range, and accurate identification of products. With its ability to streamline operations, improve traceability, and reduce manual labor, UHF RFID is becoming a critical tool for companies aiming to modernize their processes.

At ZD Technology, we offer complete RFID solutions tailored to your needs. From hardware and software integration to tag customization and system implementation, our team ensures seamless deployment for your business environment. Whether you operate in retail, manufacturing, or logistics, ZD Technology helps you unlock the full potential of RFID.

Do you need a professional team to provide you with solutions? Contact us for a quote

Let us discuss it with you.